Bumping in Rotary Evaporator During Vacuum Evaporation

Causes, Disadvantages & Solutions

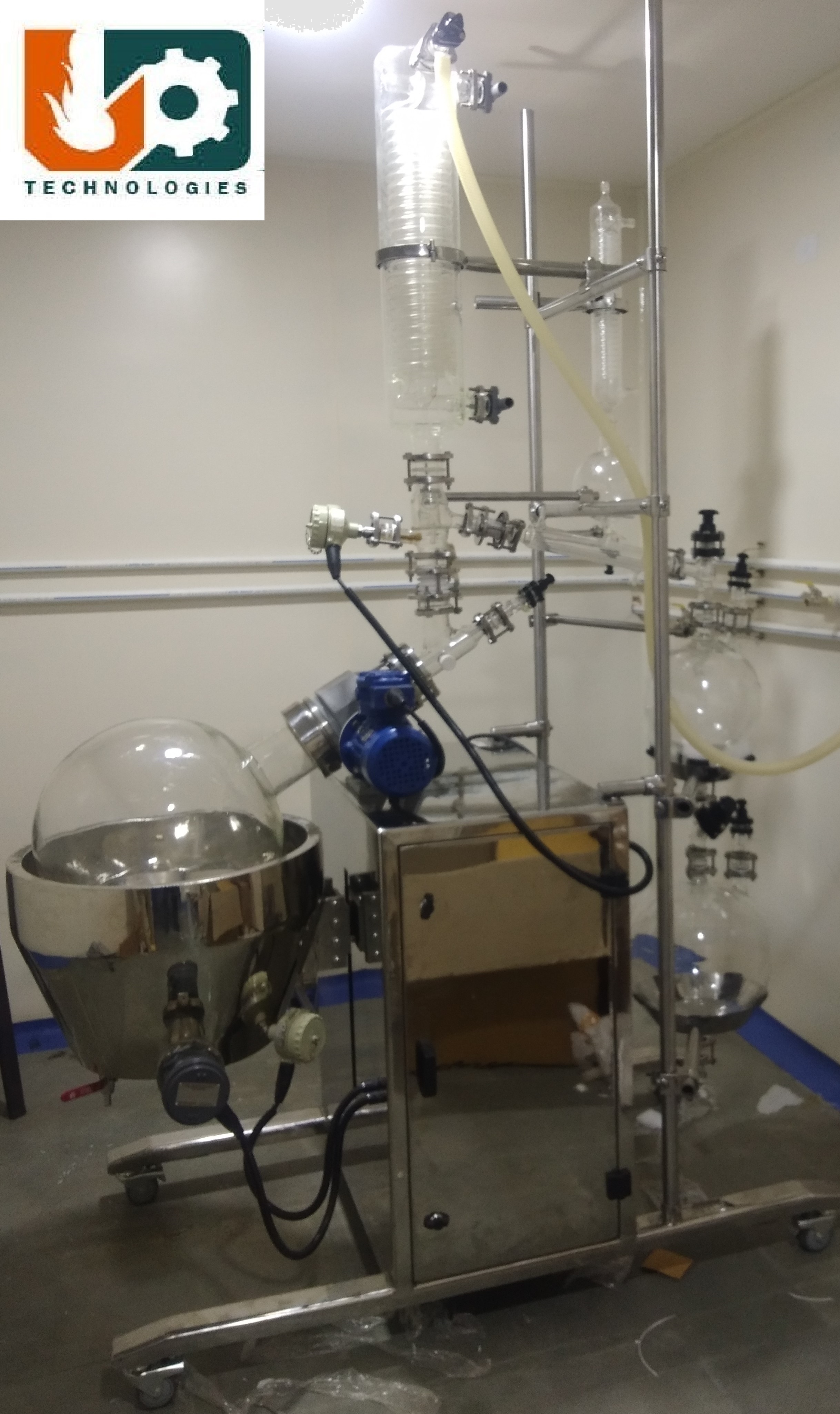

UD Technologies are Manufacturers and suppliers of Rotary Evaporators Ranges from Laboratory to Large Rotary Evaporator up to 100 litre. We now focus on a new Blog Series of Problems faced During Vacuum Evaporation like Rotary Evaporator Bumping.

Introduction

Rotary evaporators (commonly known as rotavaps) are essential tools in laboratories and production units for efficient solvent removal under reduced pressure. However, one common and often frustrating issue users face is bumping during evaporation.

Rotovap Bumping not only leads to Product and solvent loss and equipment contamination but can also damage the apparatus and delay workflows. In this blog, we’ll explore what bumping is, why it happens, and how to prevent it with practical solutions.

What is Bumping in Evaporation of Rotary Evaporator?

Bumping refers to the sudden, violent boiling of a liquid under vacuum, causing it to splash or erupt inside the evaporating flask. Unlike smooth boiling, bumping creates a disruptive burst that can carry liquid into the vapor duct or receiving flask and uncondensed vapor cloud to vacuum Pump and Environment

⚠️ Causes of Rotary Evaporator Bumping

Understanding the root causes of Rotovap Bumping helps prevent the issue effectively:

- Sudden Vacuum Application: Rapid pressure drop causes liquid to superheat and boil explosively.

- Overfilled Flask: Limited space allows little room for vapor expansion.

- Lack of Rotation: Stagnant liquid is more likely to superheat.

- Too Rapid Heating: High bath temperature causes uncontrolled boiling.

- Incorrect Flask Size: Oversized or undersized flasks increase bumping risk.

❌ Disadvantages of Bumping

Bumping is not just an inconvenience—it can lead to:

| Problem | Disadvantage |

| Sample- Product loss | Sudden eruption ejects sample |

| Solvent Losses | Sudden and larger Vapor cloungd gets uncondensed, bypassing condenser,reached to vacuum source and environment |

| Cross-contamination | Liquid enters vapor path and receiver |

| Glassware breakage | Pressure shock may damage apparatus particularly in Laboratory Evaporator |

| Cleaning burden | Equipment needs to be cleaned and dried |

| Process delays | Must stop, clean, and restart procedure |

✅ Rotovap Troubleshooting: How to Prevent Bumping: Practical Solutions

Here are effective tips to minimize or eliminate bumping during vacuum evaporation:

🔹 1. Apply Vacuum Gradually

Avoid instant pressure drops. Use a vacuum controller to ramp vacuum slowly and maintain a stable level.

A detailed explanation of how to apply the vacuum gradually shall be in the Next Blog

🔹 2. Maintain Proper Rotation Speed

Rotating the flask spreads the liquid into a thin film, improving heat distribution and reducing superheating.

🔹 3. Avoid Overfilling

Keep flask volume at 30–50% of capacity. This provides space for vapor expansion and reduces bumping risk.

🔹 4. Control Bath Temperature

Set the water or oil bath temperature based on the boiling point of the solvent. Raise the temperature slowly and avoid overheating.

🔹 5. Choose the Correct Flask Size

Match the flask size with the sample volume. Oversized or undersized flasks disrupt boiling dynamics. (for Laboratory Rotary Evaporator)

✅ Optional Equipment Upgrades

- Vacuum Controllers: Precisely manage vacuum levels and avoid pressure shocks.

- Bump Traps: Prevent splashed liquid from reaching the condenser or receiving flask.

- Please find summarised video

-

Conclusion

Bumping during vacuum evaporation is a common yet preventable problem. By understanding its causes and applying best practices—like using boiling chips, applying vacuum slowly, and maintaining proper fill levels—you can ensure a safer, cleaner, and more efficient evaporation process.

Take control of your evaporation workflow today by integrating these simple yet powerful solutions